About JRP Guitars

From log to guitar

The stump in the photo above is from a Japanese red pine tree that was being eaten away by pine weevils and had to be cut down because of this, and the guitar you see was made out of that same tree.

We decided to develop a unique guitar embracing the damaged red pine tree’s characteristics and making them shine through our artisan’s great craftsmanship. We carefully went over every process from cutting down the damaged trees to making them into completed guitars in order to get an exceptional result worth competing with a guitar made out of traditional materials. Through this project, we had an opportunity to learn about one of the largest environmental issues Japan’s forests are currently facing.

An exceptional guitar

Tonewoods imported from overseas such as alder, ash, and mahogany have been dominant materials in Japan’s guitar industry for a long time as those woods have traditionally been considered to be the most suitable for electric guitars thanks to the tones you can get out of them. This doesn’t mean that Japanese guitar manufacturers never tried to use Japanese trees as their raw material, but unfortunately, such domestic trees have generally been considered cheap alternatives to authentic tonewoods imported from overseas.

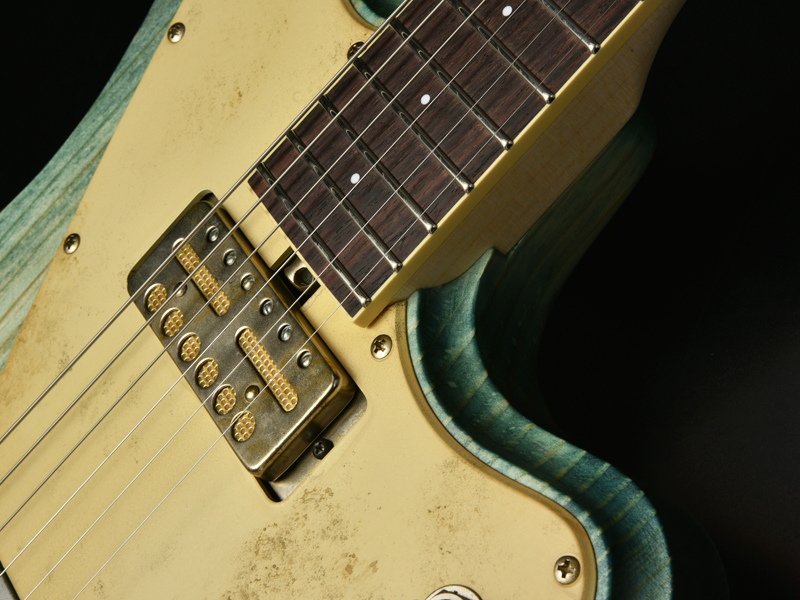

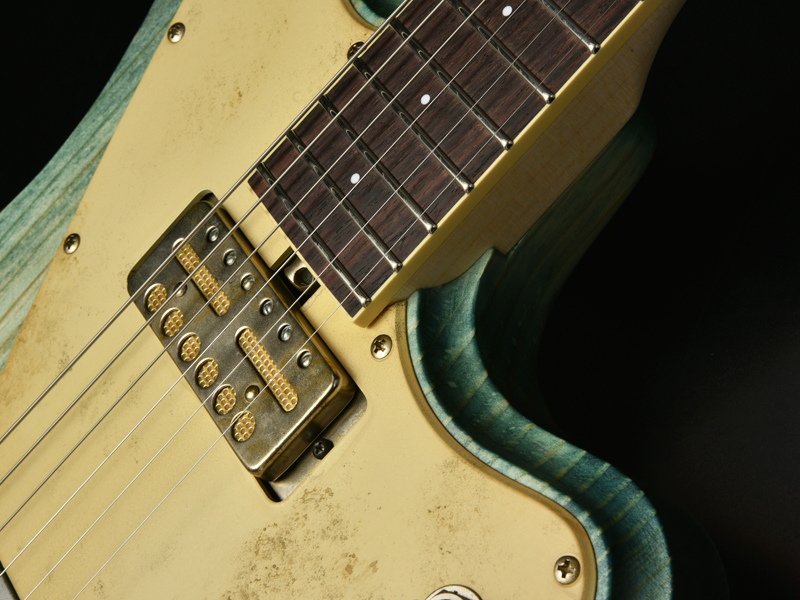

One of our goals in this JRP guitar project is to develop an exceptional guitar to defy the preconceptions of what a guitar made from Japanese materials is. Different from typical wood materials used in guitar making, the Japanese red pine tree has lots of knots and holes made by pine weevils. Instead of hiding such knots and holes by painting the guitar a solid color, we decided to give the wood a transparent finish to leave them as they are, and even emphasize them, as a unique feature of the wood. After testing various finishing methods, we decided to also try a few new finishes that add the kind of warm feeling worn-out vintage clothes give off, to the wood.

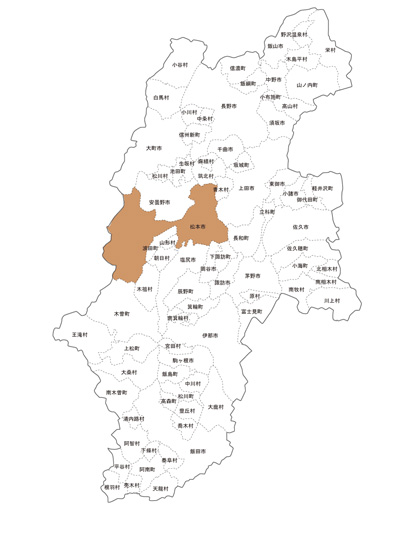

The official city tree of Matsumoto

Matsumoto city is nestled between the Japanese Alps and the Utsukushigahara Heights and surrounded by mountains whose height range anywhere from 2,000m to 3,000m. Its relatively cool and dry weather is suitable for woodworking, which has been the major industry of the city for many decades. When the guitar culture began to spread in Japan back in the ‘60s, many traditional furniture builders around the area shifted their craft into guitar making. Since then, some of them have become major guitar manufacturers that represent Japan’s guitar industry to this day.

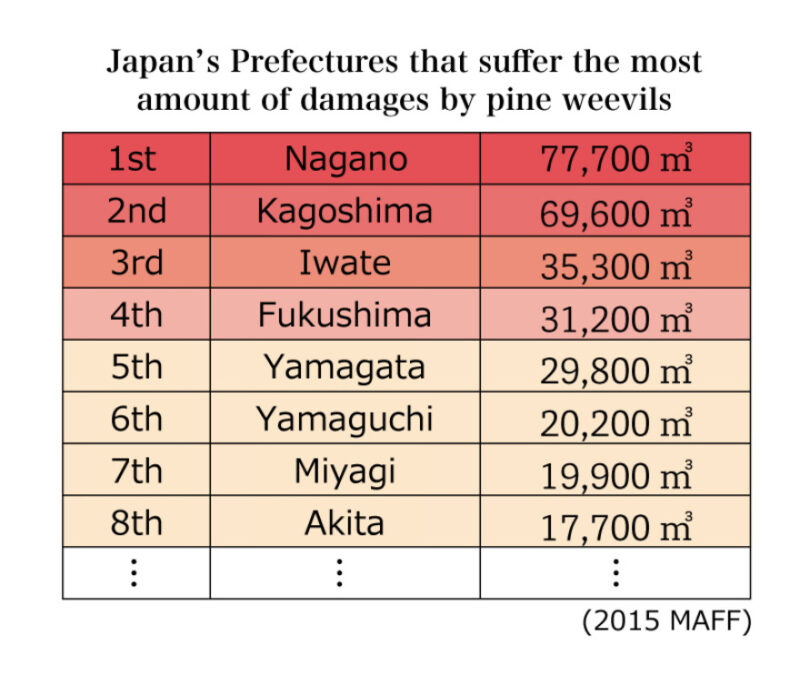

The Japanese red pine is the official city tree of Matsumoto, and entire red pine woods can be seen at almost every mountainside in the city. Deceivingly they appear to be just another typically peaceful piece of the scenery of Japan’s rural area, but in reality, many of these woods are constantly withstanding the attack of pine weevils, leaving them seriously damaged as a result. Nagano prefecture has the largest amount of trees suffering from pine weevils among all the prefectures in Japan.

Satō Tadashi, the accounting manager of Deviser is also in charge of regional forest management in the Okada area of Matsumoto city. Red pine woods in the area have been suffering serious damage from pine weevils. The trees end up withering due to the damage caused by the weevils and sometimes they collapse and fall over, presenting a hazard to the citizens. So, in order to prevent this, the withered trees are cut down before they collapse. Satō was the one who initially suggested doing something about the damaged trees going to waste by using them in our workshop.

Red Pine Timber

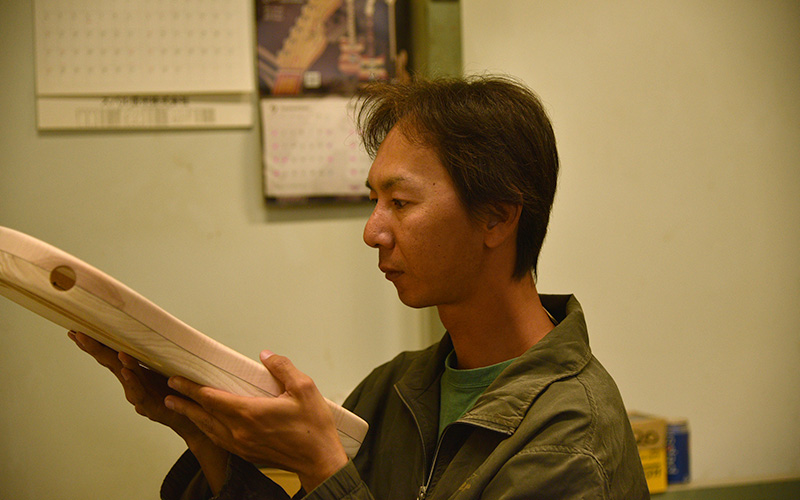

In March of 2017 one of our custom-shop builders of Headway acoustic guitars, Yasui Masto, attended the process of logging one red pine tree following the suggestion of Satō.

Even though guitar builders like Yasui work with wood on a daily basis, they are rarely involved in the process of logging. The remaining stump that was left after chopping down the tree was wet and felt quite different from the seasoned timbers that guitar builders usually work with.

Yasui and other staff members carried the log to a lumber mill with a vague feeling of unease over them while they wondered if they would really succeed at their goal of creating an amazing guitar out of this wood.

Designing an electric guitar

When we brought the timbers of Japanese Red Pine to our factory and examined the wood. We concluded that making the bodies of electric guitars out of them would actually be a viable option. The timbers had lots of knots and holes made by the weevils and the wood itself was noticeably softer than maple, which is a popular pick as the material for electric guitar’s necks. We quickly realized that it wouldn’t be a suitable material to make necks or fingerboards out of, since they require a certain level of stability and density in order to give good results.

Finish jobs to bring out the uniqueness

The problem we had to deal with was the knots and holes since such features are generally considered a flaw in the guitar industry. After some discussion, we decided to have the knots and holes remain visible on the guitar body rather than avoiding or hiding them because our aim was to develop an exceptional guitar that differs from ordinary guitars, has a unique appearance, and honors the material’s origin.

After deciding to keep the knots and holes visible, we entrusted our experienced builder Kajita who handles custom finishes to figure out a unique finishing method that would suit the wood.

Usually, we sand a guitar body with fine-grid sandpaper before the coating process so that the coating material will be evenly applied. If a body is not properly sanded, the finish will be irregular and spotting will occur all over the uneven areas. However, Kajita dared to use coarser grid sandpaper to sand the body made of Japanese red pine to intentionally create irregularity in the tone. He thought this finishing method would match this wood since its grain is not even because of the knots and holes.

As a result, the body came to have a warm feeling like that of old, worn-off furniture. The hardware and parts were also relic’d to match the finish.

The Prototype

It took us about 8 months to complete the first prototype of our JRP guitar. But it ended up being a huge success, producing a very lightweight guitar with a gentle sound that reminded us of the fresh wind blowing over Matsumoto’s plains.

This project gave us a good opportunity to learn about problems that affect the Japanese forests and consider the significance of using domestic tonewoods in our guitar making. If you ever get the chance, please, take the guitar in your own hands and give it a try, you won’t be disappointed.

As a result of everything we learned throughout this journey, we were left with a handful of amazing products of which we are very proud of.

———————

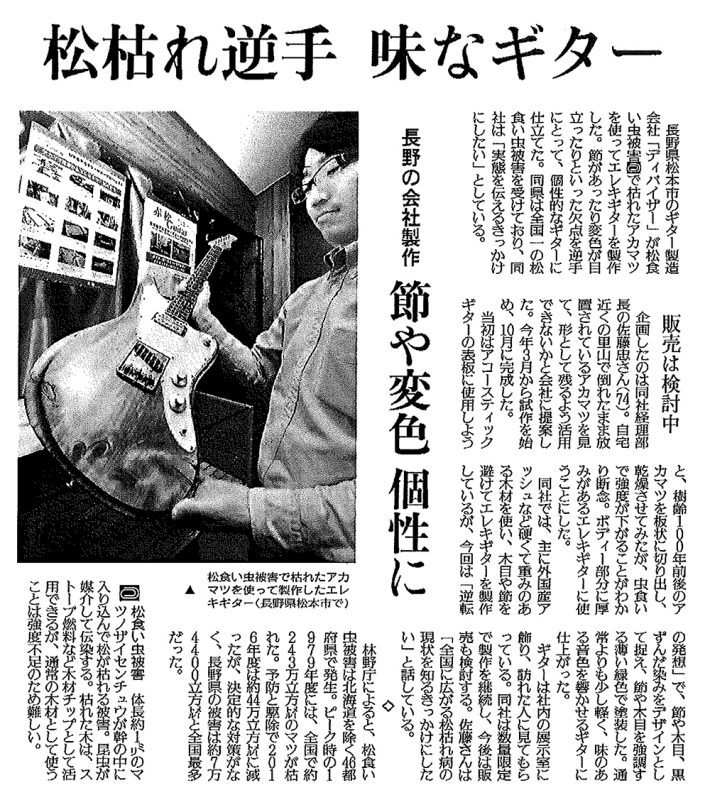

The trajectory of the JRP in Japan.

December 5th 2017, Shinano Mainichi Newspaper

・December 18th 2017 JRP Guitar was featured in the TV program “Zukudase TV” on SBC Shinetsu Broadcasting Co.

SBC Shinetsu Hoso “Zukudase TV”

http://sbc21.co.jp/blogwp/zukudasetv/

December 20th, 2017 SBC radio “Motto Matsumoto”

http://sbc21.co.jp/blogwp/matsumoto

December 28th, 2017 The Yomiuri Newspaper featured our red pine guitars in their evening edition.

Yomiuri Newspaper Website

http://www.yomiuri.co.jp/